| Model | HXMD-30.30 series | Brand | HAOXING |

| Working Width | 3100 mm | Total power | 91 kw/380V |

| Working Layers | 2 layers | transfer motor | 5.5kw*2=11kw Variable frequency drive |

| Heating area | 14 sections*2000mm =28000mm | Heating blower motor | 5.5kw*14=77kw |

| Cooling area | 1 section*2000mm=2000mm | Cooling fan motor | 3kw*1=3kw |

| Head-in area | 4000mm | transmission speed | 1-30m/minute |

| Tail out area (Natural cooling) | 6000mm | Heating medium | Thermal oil/Steam |

| Radiator | 14 sets(length2000mm*width 300mm * height 900mm) | Drying temperature | 130-180℃ |

| Drying thickness | 0.2 -4mm | Heat energy consumption | 1.8 million kcal/steam 3T |

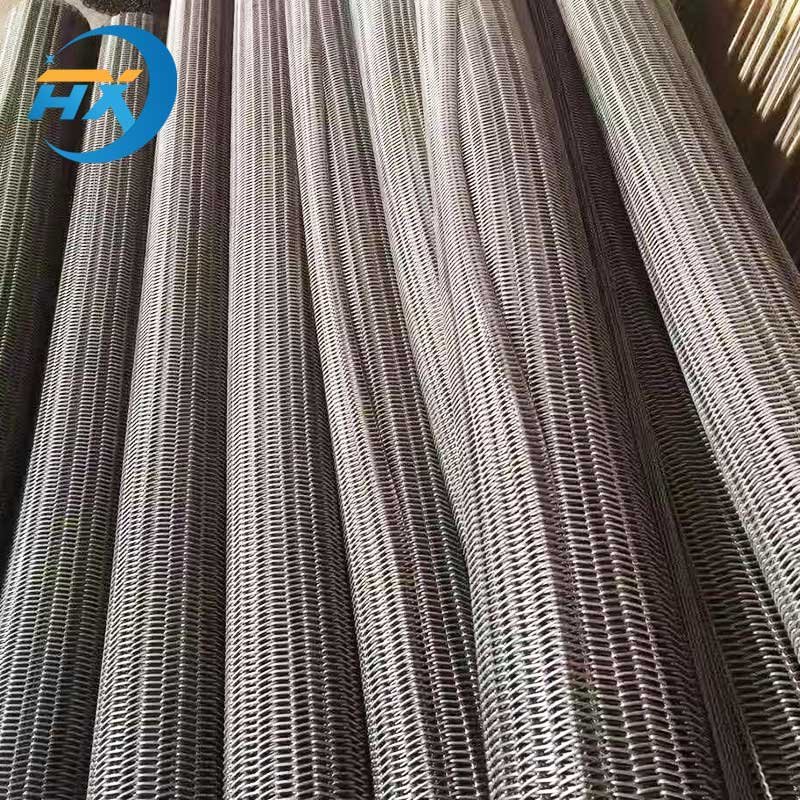

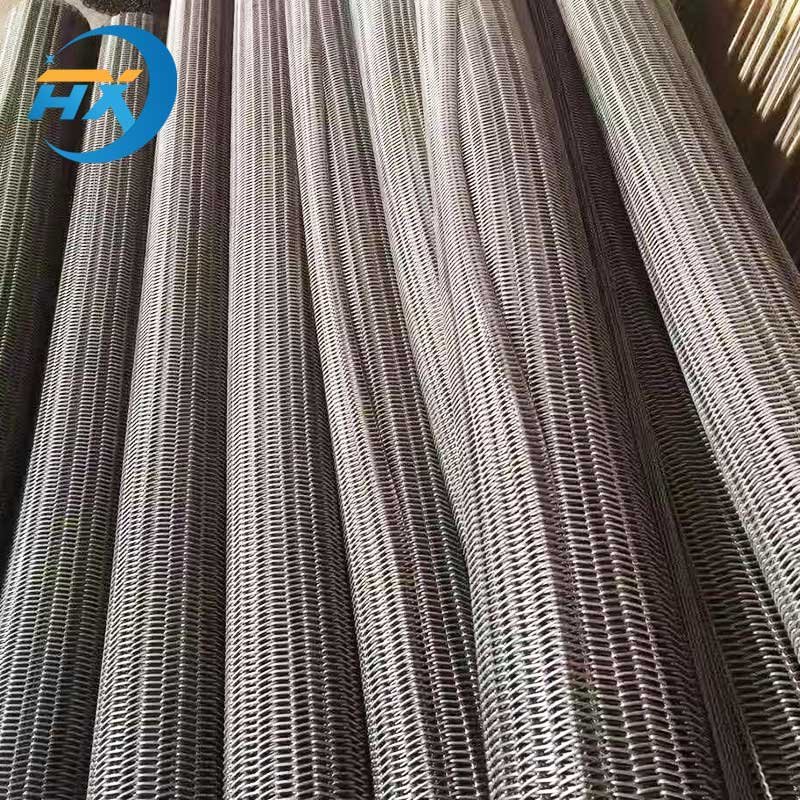

| Veneer Initial moisture content | -60% | Mesh material | Stainless steel (Infrared photoelectric adjustment) |

| Veneer final moisture content | 10%±2% | Mesh length | Length 292000mm* width 2700mm |

| Drying capacity | 1.7-2.5 cbm/hour | Mesh size | 25mm×35mm |

| Blow pipe | length 3060*width 445*height 120mm | Idler diameter | 89mm |

| Blow pipes Numbers | 260 pcs | Idler spacing | 660mm |

| Weight | 48000 kg | Number of idlers | 230 PCS |

| Dimension | Length 40m (head 4m + body 30m + tail 6m) * width 4.2m * height 3m |

| Remarks | Both drying veneer and core(0.5mm-1.5mm veneer the effect is better) Can be customized by customer’s requirement |

Other Related Machine

Spindle Log Debarker | Face Veneer Peeling Machine | Automatic Veneer Stacker

Packaging & Delivery

For woodworking machine packaging,usually packing in loose with steel wire rope reinforcement.

Delivery time:10-30days after receiving the deposit.

Service

1). 1 year’s warranty and service lifetime

2). Strictly quality control and machine testing before loading

3). Support customization according to customer requirements

4). Support online technical guidance, training

5). Dispatching technical engineers to install, guide and debug equipment is available

(0)

(0)